Green Belt

Practice

Exam

Questions

with

Answers

( In Green)

2

Q1: What method is used to increase confidence level in the results of a DOE ?

A Sequencing

B Replication

C Blocking

D Regression

Q2: If the correlation coefficient is between 0.5 to 1, it means there is a

A Negative correlation

B No correlation

C Positive correlation

D A&B

Q3: What is the best description of a hypothesis test?

A A tool for deciding if Statistical Significance exists between data

samples

B A tool for dissecting the data

C A tool for brainstorming

problems

D A tool for breaking up

the problem in smaller

parts

Q4: Which hypothesis test is similar to the 1 sample t-test but is used when the data

set is non-normal?

A 1- sample sign

B Kruskal-Wallis

C Friedman

D Mann-Whitney

Q5: Who is often called the ‘Father of quality control’?

A W. Edwards Deming

B F. Deming Edwards

C Dennis Edwards

D W. Frederick Deming

3

Q6: A typical linear regression equation would look like

A Yield = 100%

B Y = a + bx

C 3.4 = DPMO

D all of the above

Q7: Which one of the following would NOT be considered a COMMON CAUSE

VARIATION in a process? (choose the best answer)

A Serious workplace accidents that cause a shutdown for more than 2 hours

B Changes in the moods of customers every day that effect ticket sales

C Regular daily changes in average outside temperature that effect ice-cream sales

D The number of cars that pass a drive-through fast-food restaurant per hour during the

hours 12pm – 1pm each day

Q8: Which of the following activities is an example of non-value-added?

A Rework

B Inspection

C Packing

D Setup

Q9: What is the Japanese word for waste?

A Mode

B Muri

C Muda

D Mura

Q10: Which of these is NOT a Measure of Central Tendency or Position of a process?

A Inter Quartile Range

B Mean

C Mode

D Median

Q11: What is the middle value in a data set when arranged in numerical order?

A Variance

B Median

C Mean

D Mode

Q12: A Lean Six Sigma Green Belt practitioner constructs a control chart to display a

process mean and its outer limits. In such a chart, what does UCL stand for?

A Upper Control Length

B Upper Control Limit

C Upper Cycle Limit

D Upper Cycle Length

4

Q13: Which of the following is true about Control Limits and Specification Limits?

A Control limits are set by the customer

B Specification limits are set by the process owner

C It is best practice to set Control Limits narrower than Specification limits

D A suitable control chart and the right control limits will help to differential special

cause variation from common cause variation.

Q14: Which one of the following statements most accurately describes the following

string of numbers?

1.2, 1.4, 1.4, 1.8

A The mean is 1.45 and the SD approximately 0.22

B The mean is 1.44 and the SD is 0.685

C The mean is 1.1 and the SD is about 0.4

D The mean is 1.45 and the SD is 0.827

Q15: The p-value for a Moods Median test is 0.02 and the level of significance is set at

0.05, what decision is made?

A Use a different test

B Fail to reject null hypothesis

C Cannot determine

D Reject null hypothesis

Q16: What does SPC stand for?

A Standard Process Charting

B Statistical Process Control

C Standard Planning for Control

D System Performance Charting

Q17: A process with a process Sigma level of 6 over the long term would be expected

to produce which of the following?

A Approximately 3.4 defects per 1 Million Products

B Approximately 3.4 defects per 1 Million Defect Opportunities

C Approximately 3.4 defects per 1 Million Success Opportunities

D Approximately 3.4 defects per 1 Million Process Opportunities

Q18: In Lean Six Sigma, we generally consider 2 categories of variation in processes.

Which of the following are the correct 2 categories?

A Significant Variation and Practical variation

B Special Cause Variation and Common Cause variation

C Critical Cause Variation and Random Variation

D Significant Cause Variation and Low Variation

5

Q19: What is the minimum level of training that the member of a Lean Six Sigma process

improvement team requires ?

A Black Belt

B Master Black Belt

C Yellow Belt

D Green Belt

Q20: Value Stream Mapping is a technique that is considered to be part of the tool-kit

from which methodology?

A Kaizen

B Lean

C BPR

D Six Sigma

Q21: Understanding “the voice of the customer” is a technique used to provide

customers with :

A Cheaper products and services

B Buy one get one free offers

C Best in class quality

D Services and products that meet the customer expectations and needs

Q22: A product or service that does not meet the expectations of the customer is

called a

A Defective product or service

B Defect

C Problem

D Reject

6

Q23: It is always important to understand who is the customer of a process. Which of

the following is the best definition of ‘The Customer’?

A Anyone who supplies products or services to the process

B Stakeholders of the process

C Anyone who receives a product or service, or could receive a product of service from

the process

D People or groups who are responsible for the output of the process.

Q24: What Lean Six Sigma tool is used to organise and create order in the layout of

the tools and equipment in the workplace?

A SMED

B 5S

C Kanban

D Muda

Q25: The Lean Six Sigma concept called ‘Critical to Quality’ (CTQ) always focuses on

what?

A Reducing product variation

B reducing in-process inventories and minimizing product touch times

C Meeting the specific requirements of the customer

D Minimizing shipping damage

7

Q26: The name of an approved written plan of the expected benefits to the business

and the expected savings achieved from running a Lean Six Sigma project

is called a

A Project business case

B Project charter

C Savings document

D Project budget

Q27: What is the name of the technique used where a company measures its

performance against that of best-in-class companies?

A Run Chart

B Six Sigma

C Control Chart

D Benchmarking

Q28: What basic quality tools would be most applicable for a work team to use

when there is a need to follow procedures and work instructions more closely?

A Fishbone Diagrams and control charts

B Data sheets and histograms

C Pareto Charts and affinity diagrams

D Standard operating instructions and visual management

Q29: One of the purposes of using a fishbone diagram is to

A Define the problem in sequential order

B Show the relationship between parameters

C Identify the root causes of a problem

D Separate a problem into smaller components

Q30: Which of the following control charts would be best to use for a process in which

measurement data on a product is easily and inexpensively obtained?

A p-charts

B X-bar charts

C Median charts

D I-charts

Q31: Full Factorial and Fractional Factorial are both

A DOE designs

B OFAT designs

C Sigma designs

D Print designs

Q32: Which of the following is the best mathematical representation for a 2-level full

factorial designed experiment containing 4 factors?

A 2 x 4

B K

2

C 3

k

D 2

4

8

Q33: What is an experimental factor?

A A dependent variable

B An input variable for a designed experiment

C A metric of a process

D A standard deviation

Q34: A equation describes the relationship between a

Response Variable (Y) and a Predictor Variable (X)?

A Linear

B Correlation

C Regression

D Non-Linear

Q35: Which of the following statements is most true about Long Term process variation

compared to short term variation ?

A Long term variation contains all forms of variation in the process

B They are both the same

C Short term variation contains all forms of variation in the process

D Long term variation is always double (2 times) that of short term variation

Q36: Which of the following errors in a Hypothesis test is typically associated with a

"False Positive"?

A Depends on the experiments

B Type I error

C Type II error

D Type III error

Q37: Which item should not be identified in the Define Phase?

A Stakeholders

B Root causes

C The key problem area

D Business Case

Q38: Which of the following distributions is characterized by the Empirical Rule (68 /

95 / 99.7 rule)?

A Chi-square

B Normal

C Student’s test

D F statistic

Q39: In a brainstorming session, an effective facilitator should never:

A Encourage the participation of all members

B Dismiss ideas in the early stages

C Dismiss discouraging remarks

D Encourage adherence to a structure

9

Q40: How is takt time calculated?

A Available time divided by demand

B Demand divided by the amount of time available

C Time required for a task divided by demand

D Overall process time minus time required for a particular task

Q41: How many experimental runs would be required in a full factorial design if there are two (2)

levels and six (6) factors?

A 32

B 12

C 64

D 6

Q42: Which measure of a statistical distribution relates to how much it is equally

balanced on each side of the mode?

A Skewness

B Standard deviation

C Kurtosis

D Central tendency

Q43: All of the following are components of a multiple regression model EXCEPT:

A Blocks

B Correlation coefficients

C Residuals

D Intercept

10

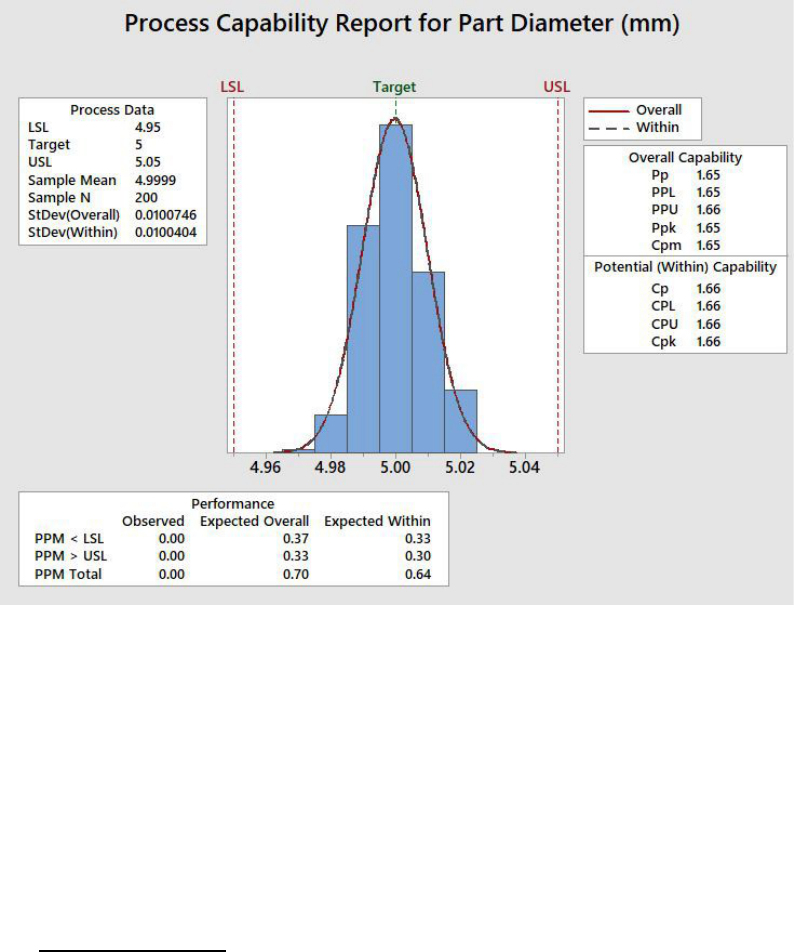

Q44: Which statement is correct about the Capability Analysis shown in Figure 1

(below)?

A There were 100 parts used in this capability study

B The Standard Deviation for part diameter is 0.00100746

C This distribution is Skewed.

D The upper specification limit is 5.05 mm

Figure 1:

Q45: Which statement is correct about the Capability Analysis shown in Figure 1

(above)?

A From this study we can predict that this process will produce less than 1 part per

million that are outside of the specification limits

B The process has a problem with centering.

C The parts have a mean average diameter between 4 mm and 4.9 mm

D The process needs significant improvements to be in control

Q46: Finish this sentence:

As part of Lean Six Sigma improvement in processes we aim to reduce the

“Batch and Queue” method of production and move towards a

method of production

A Single Team Flow

B Single Piece Flow

C Fluid Flow

D SPC

11

Q47: Which element of waste best describes the unnecessary movement of materials

and / or finished goods?

A Motion

B Inventory

C Transport / Conveyance

D Over processing

Q48: A technique used to dramatically reduce the time to change one tool set-up to

another is called

A Perfection

B SMED

C Overproduction

D Defect

Q49: Which of the 7 wastes identified by Taiichi Ohno describes the waste of a

downstream worker who cannot continue the next step of a process until a large

batch has finished processing in the upstream operation

A Over production

B Over processing

C Waiting

D Motion

Q50: Which of the following are considered to be the pioneers and “fathers” of

Quality Improvement and Statistical Process Control methods?

A Steve Jobs, Bill Gates

B Richard Branson, Alan Sugar

C Joseph Juran, W. Edwards Deming, Walter

Shewhart

D Jack Welch, Sam Walton